Mechanical Seals in the Food Industry

Equipment and machinery in the processed food industry are often held to high standards for cleanliness and precision, which can be difficult to meet with conventional packing seals. Switching to mechanical seals is a great way to improve the cleanliness and serviceability of your operation. With so many mechanical sealing options, which seal is right for your application?

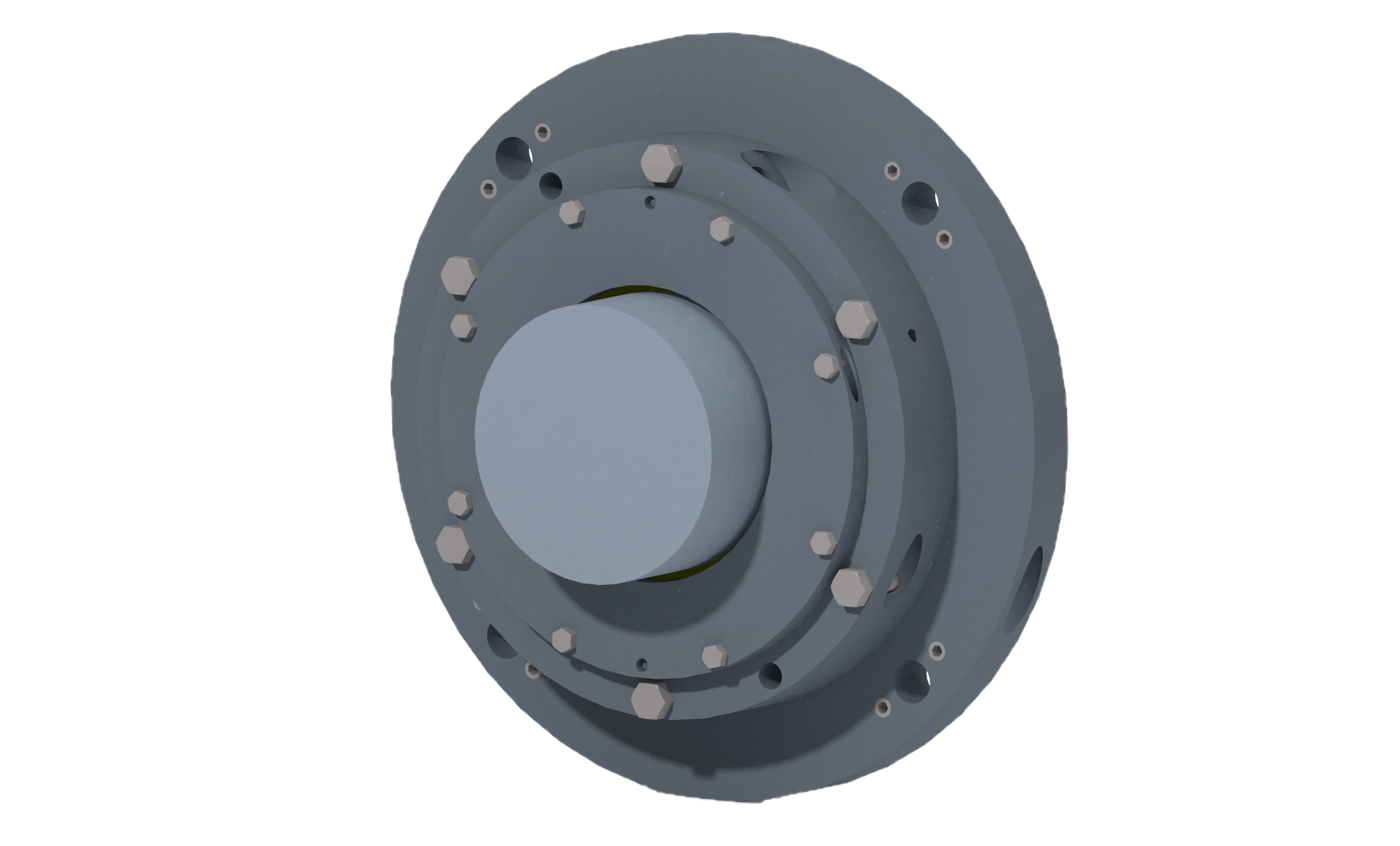

OFS Seals:

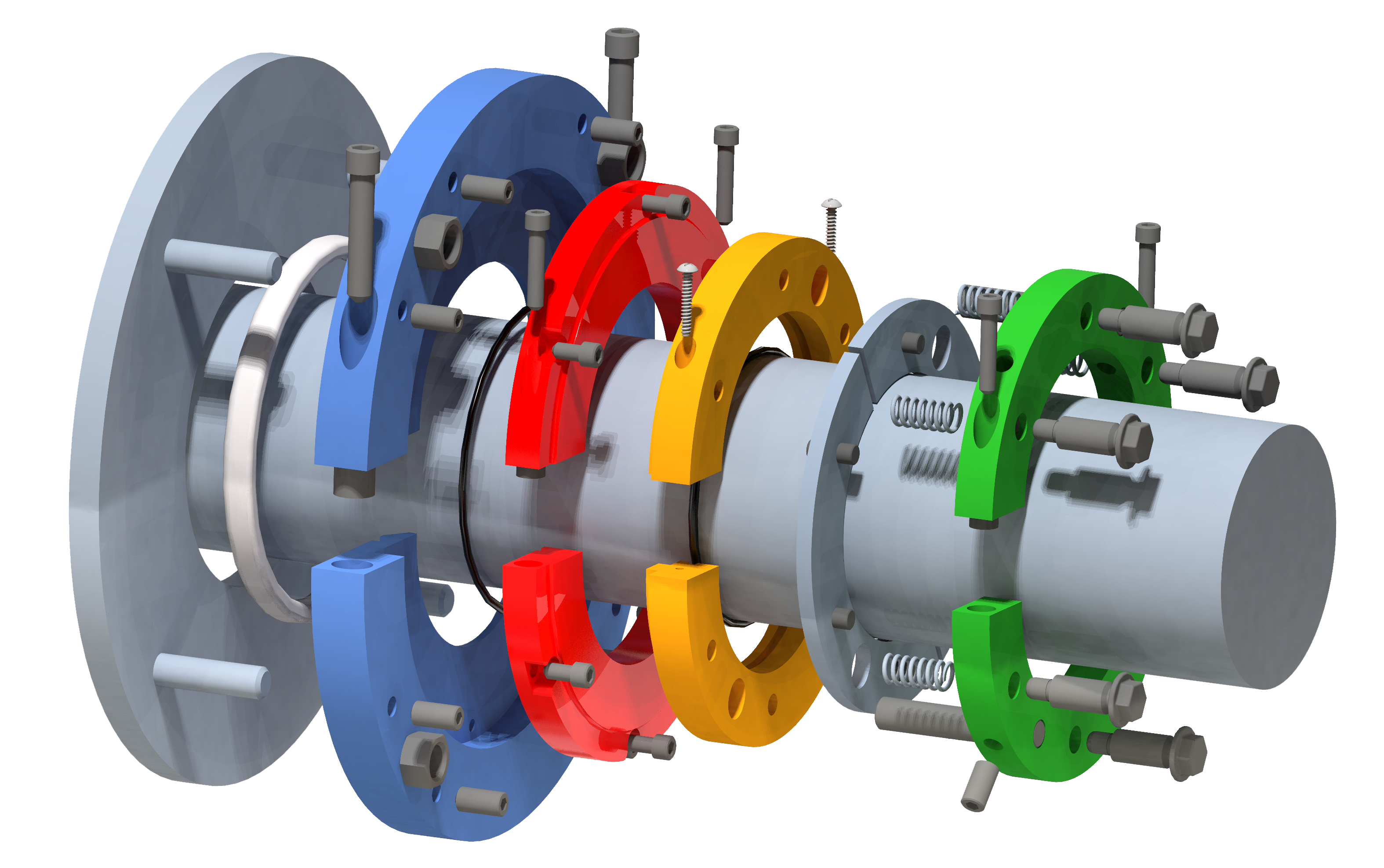

The OFS seal is MECO’s gold standard for industrial food processing equipment. Unlike other mechanical shaft seals, OFS seals have no external housing. All components are visible and accessible for highly efficient cleaning, drying, and inspection. OFS seals use a self-adjusting drive assembly and are entirely air-free. MECO offers two styles of OFS seals to meet the needs of your application.

The OFS Type 2 is ideal for dry applications with ambient pressures and temperatures. It is often used in dry powder blending and mixing for products like spices, bakery mixes, or other food powders.

The OFS Type 1 is ideal for hot and/or wet applications. Its spring-loaded drive collar can accommodate axial shaft growth or shrinkage that is often experienced during thermal cycles. The OFS Type 1 is often used on cookers and wet mixers.

All OFS seals are available fully split and custom engineered to your specific application. The simple, split design allows for fast installation and maintenance.

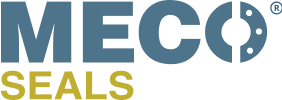

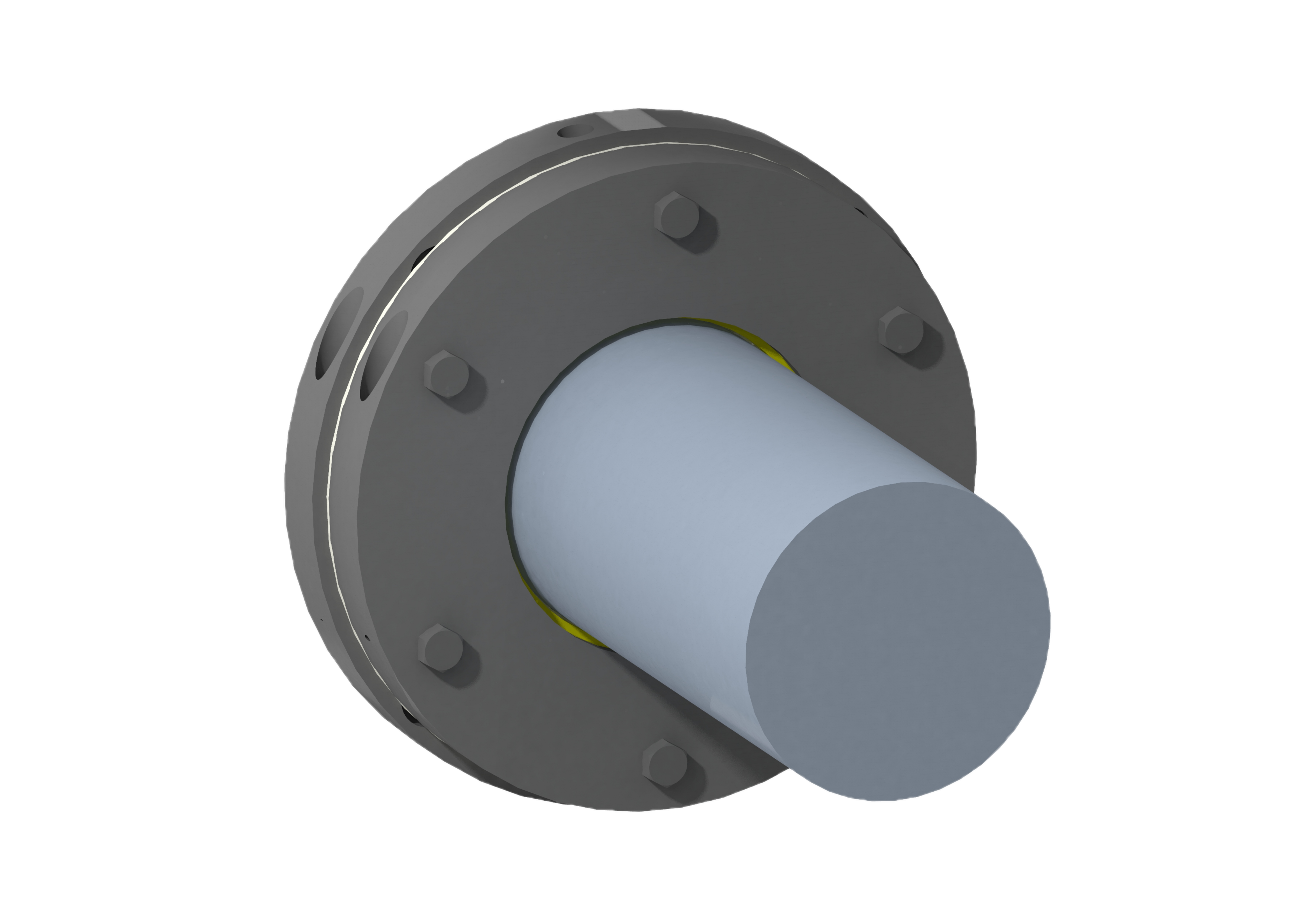

AH Seals:

The AH seal is MECO’s work horse for industrial food processing equipment. It is highly versatile due to its low axial profile, affordability, and simplicity. The AH seal’s air purge helps to seal products with small particle sizes and is advantageous in cases where an air or inert gas barrier must be maintained between process and atmosphere. It can be manually adjusted through the removal of adjusting gaskets. AH seals can be used for most applications without extreme heat or thermal cycling. They are often used on dry powders and wet slurries.

AH seals are available fully split for ease of installation and service and, like all MECO seals, are custom engineered to your application.

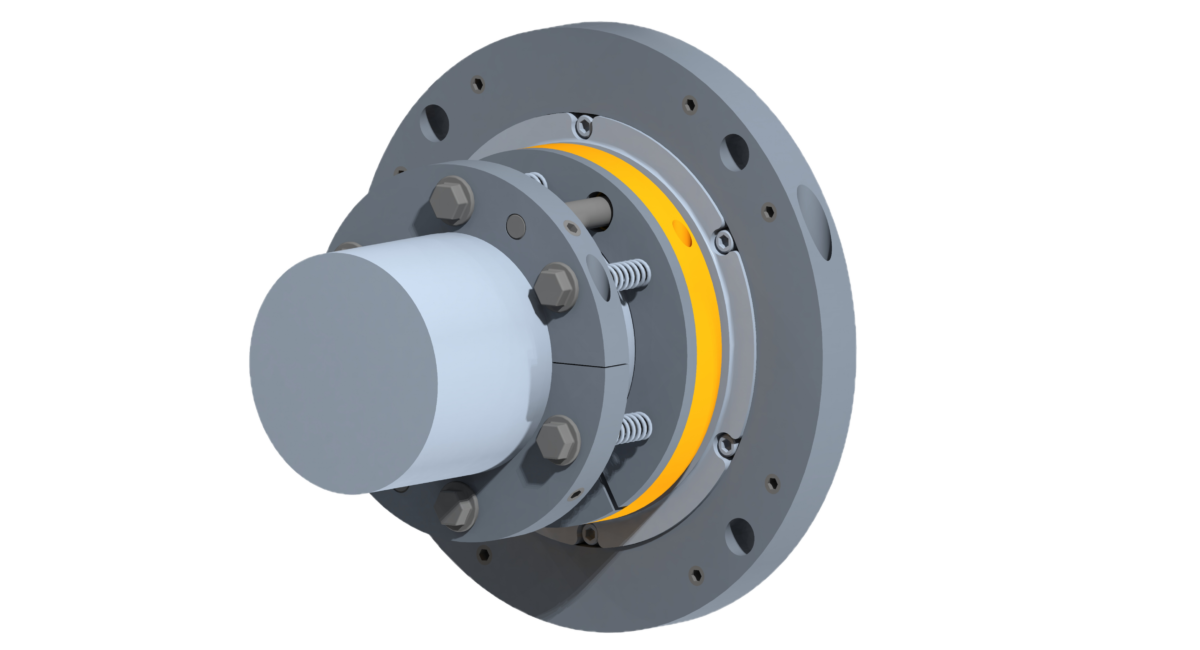

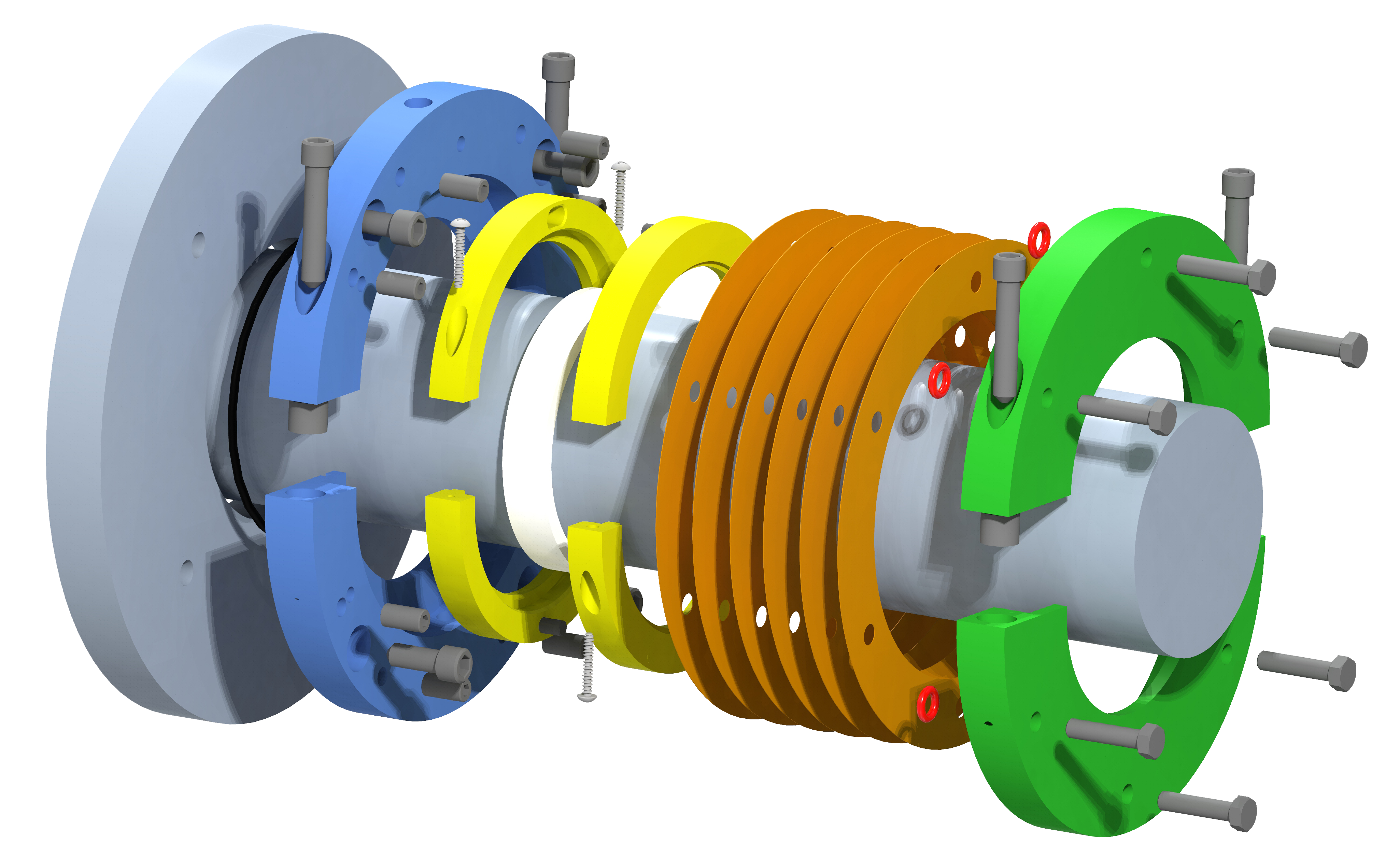

SC Seals:

The SC seal is a versatile, double-faced seal that can be used with or without an air purge. Its unique hose clamp calibration allows for field adjustment without disassembly. The SC seal is a semi-custom seal with several off-the-shelf components that help in reducing lead times and costs. It is often used in the chocolate industry but can also be used to seal powders or slurries.

Similar to the OFS and AH, the SC is fully split and is custom engineered to your application

Why MECO Seals:

MECO seals are an excellent way to be proactive about food safety and product loss. Product leaks are not only a nuisance that degrade your working environment but they can also have a significant effect on food safety. Unlike packing and lip seals, MECO seals are easy to clean and sanitize and are non-abrasive to shafts. MECO’s fully split designs significantly reduce install, cleaning, and rebuild times, and with proper maintenance, can save on costly downtime with their high reliability. A MECO seal today keeps emergency maintenance away!