MECO Seals in Battery Production

MECO seals are a reliable solution for wet and dry mixing in the battery industry. Our fully split AH Type 2 and EP Type 3 seals are popular options in battery production and can be custom engineered for your machines and process. Both seals help to improve vacuum containment efficiency and eliminate product loss with minimal maintenance.

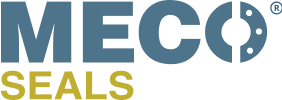

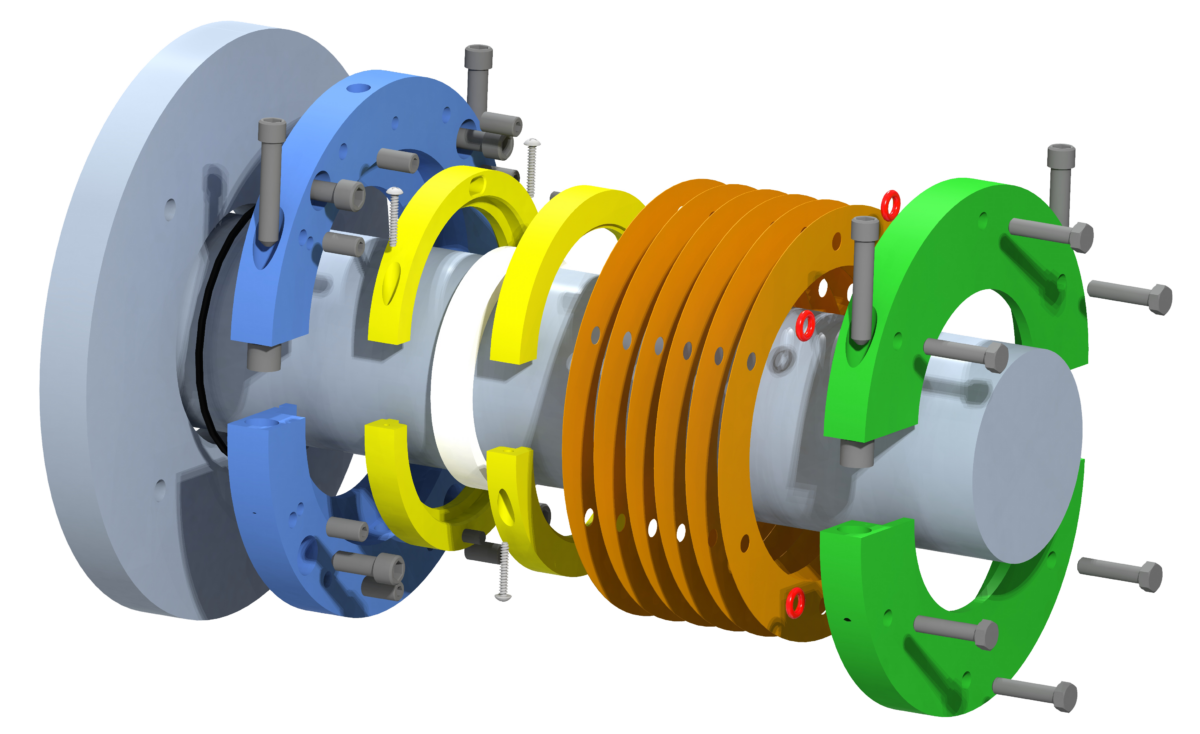

AH Type - 2

The AH Type 2 is a great choice if you have:

• High runout

• Axial space restrictions

• Ambient to moderate temperatures

• Minimal thermal fluctuations and growth

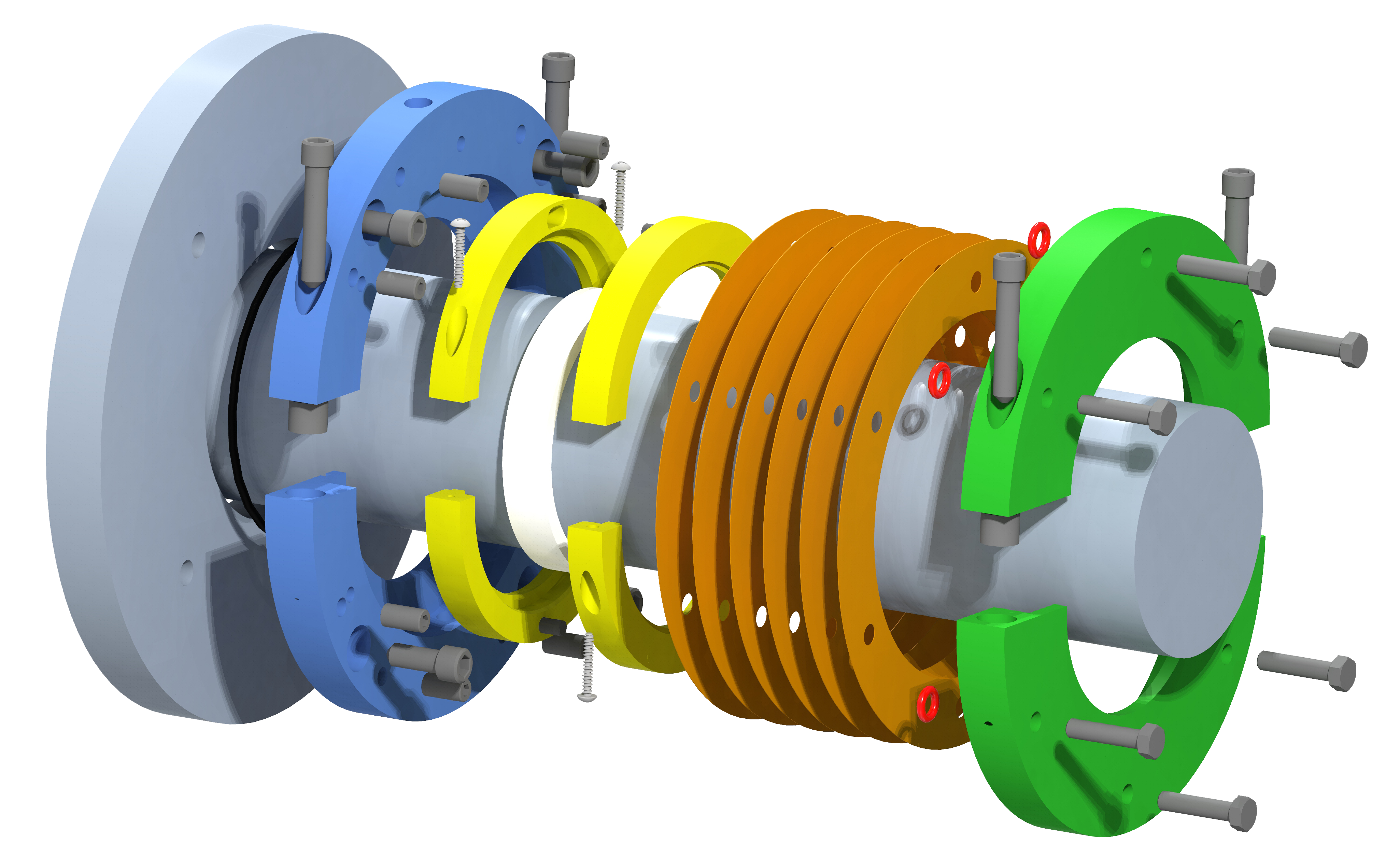

The EP Type 3 is a great choice if you have:

• High runout

• Ample axial space

• High temperatures

• Frequent thermal fluctuations and growth

Why Temperature is Important in Seal Selection:

Your machine’s operational temperature and thermal cycle play an important role in the selection of a MECO seal. The EP Type 3 is better suited for higher temperatures than the AH Type 2 by solving two common problems.

1. Rotor Growth

The AH Type 2’s polymer rotors are driven by an elastomer ring. During normal operation, the rotors are affected by the machine’s operating temperature and the frictional heat from the seal. If the rotors get too hot, they grow off the drive elastomer causing the rotors to slip and stop rotating with the shaft. The result is an increase in elastomer wear, shortening the life of the seal. To solve this issue, the EP Type 3 uses a metal drive collar instead of an elastomer to lock the seal’s rotating components to the shaft.

2. Nonuniform Growth of Shaft and Vessel

During a battery mixing process, the vessel walls and the shaft often operate at different temperatures, creating dissimilar growth between the vessel and the shaft. A common example occurs when the vessel walls are cooled while hot product is dumped into the mixer. Unlike the AH Type 2, the EP Type 3 is specifically designed to accommodate dissimilar growth between the vessel and shaft by allowing the drive collar to slide axially within the seal while driving the seal’s rotors.

Why MECO Seals:

MECO seals are an excellent way to be proactive about product loss. Leaking seals are not only a nuisance that degrade your working environment but can also have a significant effect on process efficiency and safety. Unlike packing and lip seals, MECO seals are non-abrasive to shafts and are designed for minimal purge gas consumption. MECO’s fully split designs significantly reduce install and rebuild times, and with proper maintenance, can save on costly downtime with their high reliability. Improved seal integrity also enhances environmental quality by containing toxic process materials. A MECO seal today keeps emergency maintenance away!