MECO Products

Client-tailored, industry-specific seal solutions

With nearly four decades of experience as innovative shaft seal solution providers, the MECO team has faced and overcome a long list of complex, industry-specific sealing challenges for a wide range of manufacturing customers. As our capabilities have grown—with seals that tolerate ¼” and more of diametric runout—our customer base has expanded into new industries.

Today, MECO seals are trusted by food, battery, plastics, marine, pulp & paper, and building materials manufacturers worldwide, where we effectively eliminate common issues with pump seals, mechanical packing, and lip seals of all types.

As our customers can attest, the benefits of MECO seal performance are critically important, producing measurably positive impacts on:

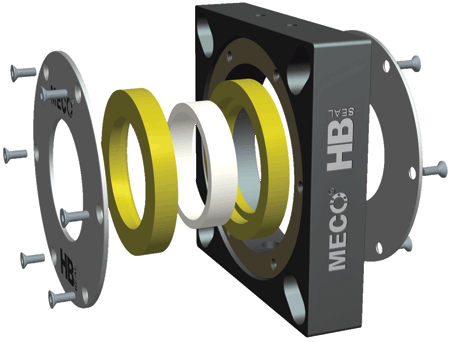

The MECO HB seal model is the best choice in sealing technology for screw conveyors.

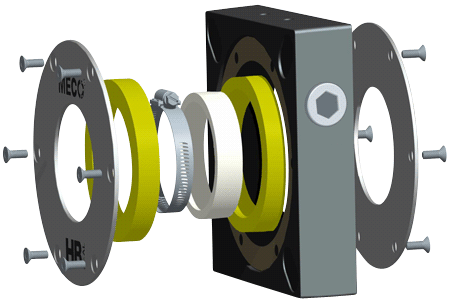

The MECO HC seal model is the best air-free choice in sealing technology for screw conveyors.

ATEX is a series of explosion prevention standards, codified in EN 94/9/EC.

The MECO-MB seal model is an elastomer driven, contacting face seal designed to fit inside of an existing stuffing box.

MECO IS-301L (left access) or MECO IS-301R (right access) compressed gas panel.

A precision Wera adjustable torque screwdriver offers accurate and repeatable adjustment of the HC seal’s clamp.

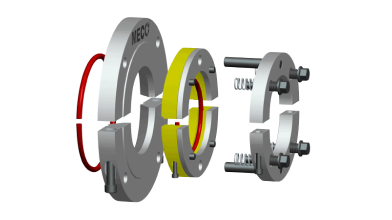

The MECO OFS Type-1 seal is frequently the best, fully-split seal for vacuum, low pressure, and abrasive applications.

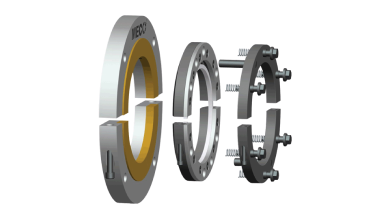

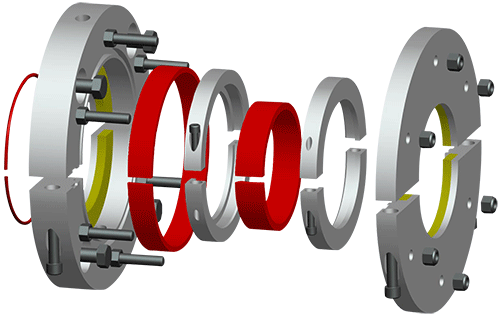

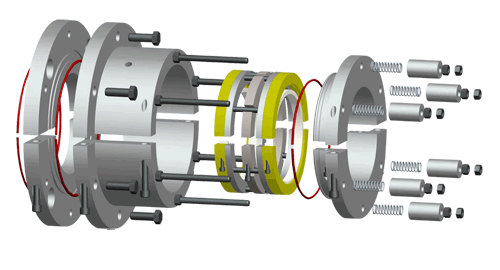

The patented MECO OFS Type-2 model is the best choice in many sealing applications for low to moderate speed equipment.

The SEA-GARD provides an effective rudder post seal in abrasive, coastal waters.

The MECO AH Type-2 model is the best choice for fitting a split seal in limited space on small to large shaft diameters.

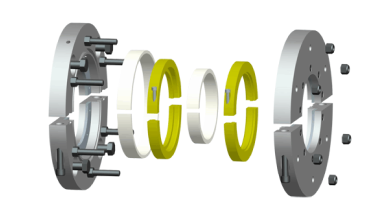

The MECO EA Type-1 fully-split seal model is a great selection when sealing wet slurries.

The MECO EA Type-2 model is the best choice in many sealing applications for low to moderate shaft speeds on small to very large shaft diameters.

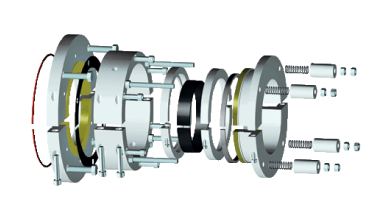

The MECO EP Type-1 seal model is the best choice in wet sealing technology on moderate to very large shaft diameters entering the vessel from any direction.

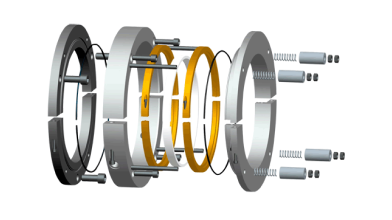

The MECO EP Type-2 model is the best choice for many sealing applications with low to medium-high shaft speeds, on small to large shaft diameters.

The MECO EP Type 3 model is the best choice in split sealing technology for horizontal dryers and reactors in vacuum service.

Custom Seal Solutions

Because MECO seals are customized for each customer’s unique industry, application, and equipment, our solutions offer unparalleled performance—effectively preventing the escape of dry powders, bulk materials, pastes, slurries, liquids, and vapors. We also produce sanitary seals for food and pharmaceutical applications.

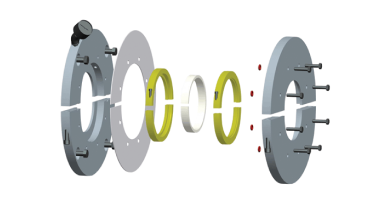

Most MECO seals feature fully split designs that allow for easy installation, maintenance, and rebuilding without the added time and expense of drive removal. Whether split or unsplit, our seals are designed to address each application’s unique configuration, taking into consideration:

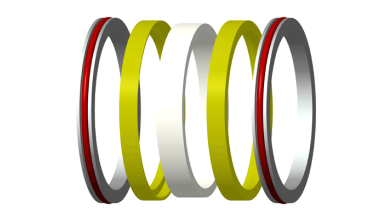

In every application, our seals are designed to operate on a plane perpendicular to the shaft without relative motion between the shaft and seal—eliminating the abrasion and high operating temperatures that are associated with common mechanical packing alternatives.

These four categories, in conjunction with spatial and operational parameters, are used to form our seal models AH, EA, EP, HB, MB, SC and OFS. These six basic models branch out into many seal types to meet customer's specific needs.