Current news and information on MECO technology at work

When our industrial clients turn to us with uniquely challenging seal applications, we welcome the opportunity to apply what we know, to innovate, and to arrive at custom solutions that work. Our case studies highlight some of our most compelling projects, and shed light on the MECO Seal process.

[parent] => 0 [count] => 12 [filter] => raw )MECO Case Studies

Current news and information on MECO technology at work

When our industrial clients turn to us with uniquely challenging seal applications, we welcome the opportunity to apply what we know, to innovate, and to arrive at custom solutions that work. Our case studies highlight some of our most compelling projects, and shed light on the MECO Seal process.

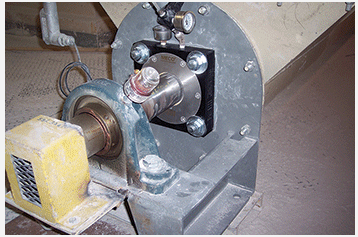

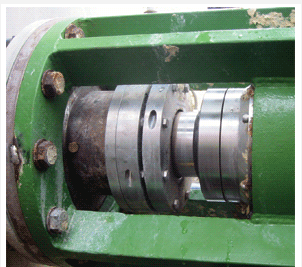

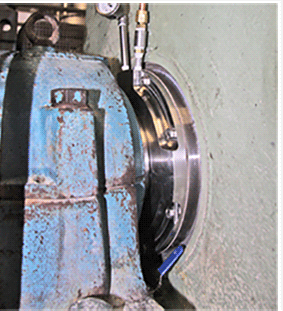

This article outlines how seals work and discusses application examples of seals and bearings used with mechanical conveyors. No application is routine, even for screw conveyors

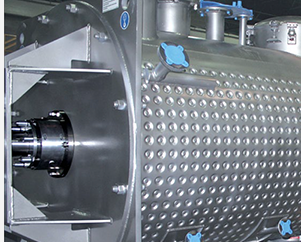

Rotating shaft sealing specifications for batch blenders and cookers in the food and beverage industry are some of the most demanding.

Facilities are constantly tasked with improving productivity and equipment reliability levels.

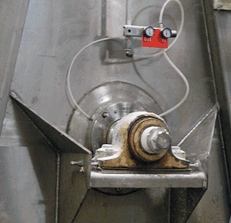

Screw conveyors are the workhorses of most process industries, and downtime can be crippling to a production schedule.

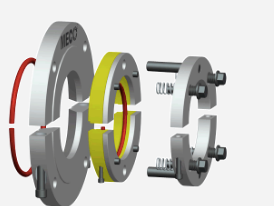

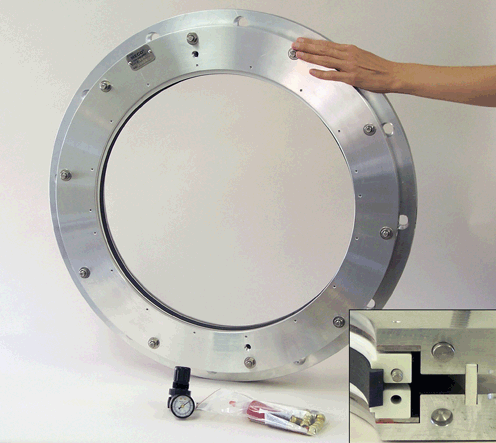

Designing a mechanical shaft seal to meet the specific needs of your machinery and process parameters requires sharing information.

Mechanical seals are more than 100 years old, originating in 1905 when they were used in refrigeration compressors.

There are often misconceptions surrounding the availability of contacting, polymeric rotary shaft seals.

A soybean oil extraction plant in Alabama reports a marked reduction in hexane loss after replacing the packing glands on its extractor, feeder, and discharge screw shafts with custom-engineered shaft seals.

When your blender seals cause between $500-600 worth of product per day to end up in the mop bucket, either the seals have to go or the blender does.

W.F. Taylor Co. Inc. (“Taylor Adhesives”) of Dalton, Georgia manufactures state-of-the-art, environmentally friendly adhesives for flooring installation.

Custom designed mixer shaft seal eliminates waste and hazards .To produce its soy ingredients, this manufacturer relies heavily on a 7-metric ton ribbon blender.

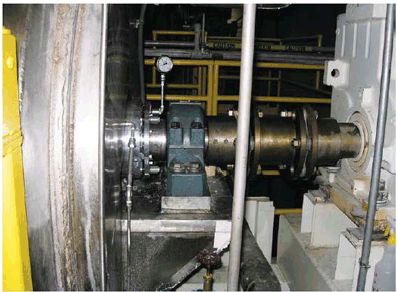

Replace a seal, save a $1 million dollar project PREVENTIVE MAINTENANCE Replace a seal, save a $1 million project By Matt Defosse Good things come in small packages, with a good example to be found at additive supplier Amfine. Running into serious problems with a dryer used to prepare nucleating agents, the company was able to replace a seal on …