Need A Shaft Seal?

What basic information does a manufacturer need to start a quote?

Designing a mechanical shaft seal to meet the specific needs of your machinery and process parameters requires sharing information. To ensure the best design and seal performance, open dialog between the customer and the seal manufacturer starts with the first inquiry.

To start the discussion and allow a chance for a rapid proposal, providing available specifications or your best estimates to the bullets listed in phase 1 is sufficient. As the interest and feasibility are met, expanding the discussion into Phase 2 and Phase 3 confirms and refines the 1st phase results.

Phase 1

Understanding the basics for the initial feasibility and proposal stage.

• Shaft diameter:

• RPM:

• Shaft position: Horizontal, Vertical or Inclined.

• Pressure ranges:

• Temperature ranges:

• Duty Cycle:

• Explosive concerns (y/n):

• Process material: liquids, slurries, pastes, dry powders, vapors, all that apply.

• Any known or specified materials of construction available to consider or eliminate, please share?

If TBD, we start with typical materials for the outlined parameters.

Phase 2

Understanding the physical space available. checking fit, sizing and serviceability of the seal.

• Axial space open along the shaft from the mounting surface to the bearing, coupling or axial obstructions.

Note any steps in shaft diameters or sleeve protrusions too.

• Radial clearance around the shaft.

If obstructed at one or two positions, how far away and how much open space is available.

• Mounting bolt pattern, bolt or stud type, quantity, siz e and position on a clock face.

• New build or existing equipment?

Phase 3

Expanding upon the understanding of the operational parameters, assembly of the machine and application history.

• Expanded discussion on first two phases to refine and define the specifics of the duty cycle, operating conditions and possible cleaning methods or service cycles.

• History of the equipment

• History of the process

• Past sealing approaches

• Materials of construction review

• Purge and quench controls and approaches

• Explosion protections or ATEX review

• Other details specific to the application

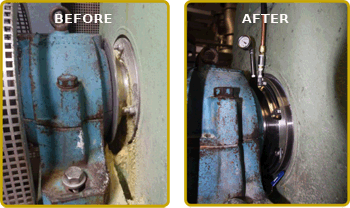

Providing application information for a mechanical seal may seem overwhelming at first, but breaking it down into phases simplifies the task. Sharing the knowns or best estimates begins the process and determines if the other phases merit action or you may uncover a standard “off the shelf” mechanical seal meets the needs. As the 3 Phases are completed and discussions are expanded, clarity emerges and the fun begins. Designing the best approach for serviceability, long life, high performance, predictability and maximized profits are key criteria to expect from your mechanical seal manufacturer. Custom mechanical seal designs are sometimes needed for process machinery other than pumps. Most process machinery conforms too few sizing standards and uses of the machinery vary over a wide spectrum of industries, furthering the need for a custom designed solution versus using a standard pump or top entry mixer seal.